|

Xi'an Taijin Industrial Electrochemical Technology Co., LTD.

|

Gold Index: 122077

| Price: | 1.0 USD |

| Payment Terms: | T/T,L/C,WU,Paypal,Money Gram |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

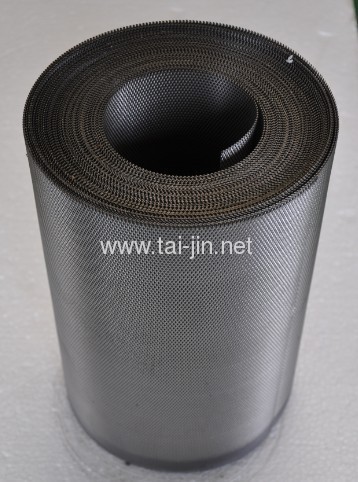

MMO Mesh Ribbon Anode

Mixed Metal Oxide (MMO) Mesh is a durable anode designed for ImpressedCurrent Cathodic Protection systems of steel structures and steel reinforcement concrete. The MMO coating, with industrially proven lifetime characteristics,ensures an even current distribution.

1. Substrate & Coating

1) Titanium ASTM B265 Grade 1

2)Coating: Mixed Metal Oxide-IrO2+Ta2O5

2.Parameters:

1)Other specification can be availableas client's requirement.

width (mm) | length (m) | thickness (mm) | Current Rating | surface area (m2) | mesh dimension (mm) |

10 | 76 | 1.3 | 2.8ma/m | 1.85 | 2.5x4.6 x0.6 |

13 | 76 | 1.3 | 3.5ma/m | 2.4 | 2.5x4.6 x0.6 |

19 | 76 | 1.3 | 5.28ma/m | 3.6 | 2.5x4.6 x0.6 |

1220 | 76 | 1.98 | 37.8ma/m2 | 92.9 | 25x50 x0.89 |

1220 | 76 | 1.98 | 24.4ma/m2 | 92.9 | 34x76x0.89 |

2) Anode Performance:

Current Rating at 100 mA/m2(10mA/ft2) | 2.8mA/m(0.085mA/ft) |

Expected life(NACE Standard TM02944-94) | 100years |

Catalyst | Mixed Metal Oxide(MMO) |

Maximum anode concrete interface current density: | |

FHWA limit | 110mA/m2(10mA/ft2) |

Short-term limit | 220mA/m2(20mA/ft2) |

3.Application

Reinforced concrete, Bridge,Pier Floodcontrolembankment;

4. The Third Party Certificate

Test Cetificates from Det Norske Veritas (U.S.A.), Inc. Under NACE TM0108-2008

Production Assessment from Bureau Veritas

5. Quality Assurance

Quality Assurance of MMO Mesh Ribbon

Strict quality procedures are followed throughout the whole process from raw materials to finished products to ensure coating adhesion and loading.

1) Chemical Composition- ASTM B265 Gr1

Element | Content % |

Nitrogen | 0.03 Max |

Carbon | 0.08 Max |

Hydrogen | 0.015 Max |

Iron | 0.2 Max |

Oxygen | 0.18 Max |

Residual(each) | 0.1 Max |

Residual(total) | 0.4 Max |

Titanium | Balance |

2) Visual Coating Uniformity, Color and Scratch

3) Coating adhesion

Three Steps

First, feeling the surface of tubular anodes in a pair of white gloves to observe

whether black mark is left on the gloves

Second, paste with transparent tape to observe whether black mark is left on the

Tape

Third, bend the ribbon to observe whether the coating fades

4) Accelerate Life Test

NACE standard TM0108-2008, 15000A/m2, 1mol/l Na2SO4

7. Quality Assurance of MMO Mesh Ribbon

Strict quality procedures are followed throughout the whole process from raw materials to finished products to ensure coating adhesion and loading.

1) Chemical Composition- ASTM B265 Gr1

Element | Content % |

Nitrogen | 0.03 Max |

Carbon | 0.08 Max |

Hydrogen | 0.015 Max |

Iron | 0.2 Max |

Oxygen | 0.18 Max |

Residual(each) | 0.1 Max |

Residual(total) | 0.4 Max |

Balance |

2) Visual Coating Uniformity, Color and Scratch

3) Coating adhesion

Three Steps

First, feeling the surface of tubular anodes in a pair of white gloves to observe

whether black mark is left on the gloves

Second, paste with transparent tape to observe whether black mark is left on the

Tape

Third, bend the ribbon to observe whether the coating fades

4) Accelerate Life Test

NACE standard TM0108-2008, 15000A/m2, 1mol/l Na2SO4

8. Products

Raw Materials

Half-finishedProducts

Finished Items

Packages

Xi'an Taijin Industrial Electrochemical Technology Co., LTD. [China (Mainland)]

Business Type:Manufacturer

City: Xi'an

Province/State: Shaanxi

Country/Region: China (Mainland)