|

Xi'an Taijin Industrial Electrochemical Technology Co., LTD.

|

Gold Index: 122077

| Price: | 2.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Taijin anode coatings may be selected to match fresh water, brackish water, seawater, coke, or sand environments.

MMO Coated Titanium Rod Anode

MMO Rod Anodes are comprised of atitanium substrate with a mixed metaloxide coating. The mixed metal oxide is acrystalline, electrically conductivecoating that activates the titanium andenables it to function as ananode.

1.Substrate:

1) Titanium ASTMB338 Grade1orGrade2

Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

2)CoatingCatalyst:MixedMetal Oxide (Main Component: Iridum Oxidefor soil&fresh water, RutheniumOxide for Sea Water)

2. Features

High Current Output

Low Coating Wear Rate

Five Year ProductWarranty

Also available as RodAnode Assemblies

3.Applications

Process Vessels

Water Condenser Boxes

Heat Exchangers

Water IntakeStructures

Groundbed

4. Quality Assurance

The following quality assurance is made throughout themanufacturingprocess:

1 ) Certification of compliance of the titanium substrate.

2) The sizeand length

3) The certificate of origin

4) AcceleratedLifeTest using acid solution under NACE Standard TM0108

5) Visual inspectionofMMO coating and cable

6)MMO coating adhesion test

5.Speicifacations

Diameter (mm) | Length(mm) | Surface Area(m2) | Working life(year) |

3.2 | 1000 | 0.01 | 20 |

6.4 | 1000 | 0.02 | 20 |

12.7 | 1000 | 0.04 | 20 |

19 | 1000 | 0.06 | 20 |

25 | 1000 | 0.08 | 20 |

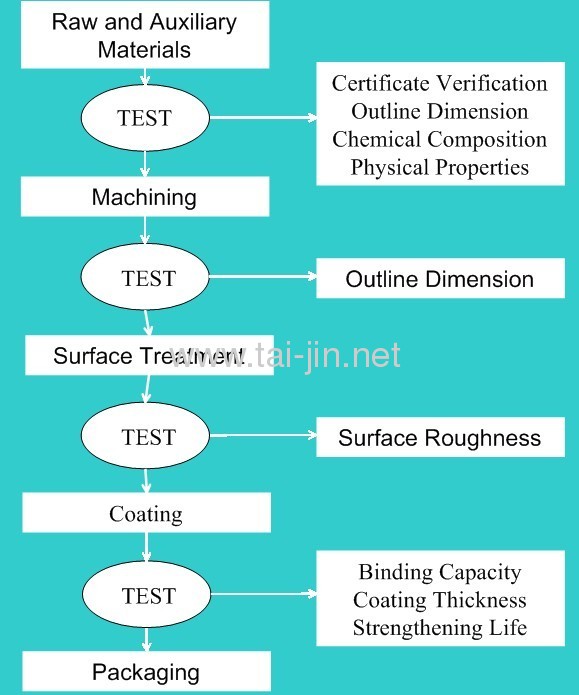

6.Production Flow of MMO anode:

Raw material

--- Shearing

--- Machining

---welding

--- Blasting

---Picking

---- coating

Manual brushing

Automatic coating

---Inspection---Package

Accelerated Life Test Coating Thickness Test

Packaging

7.The List of Products from Xi'an Taijin

1) Anode for Cathodic Protection

a) MMO Titanium Tube Anode/Platinized Titanium Tube Anode

b) MMO Titanium Disk Anode/ Platinized Titanium Disk Anode

c) MMO Titanium Rod Anode/ Platinized Titanium Rod Anode

d) MMO Titanium Sheet Anode/ Platinized Titanium Sheet Anode

e) MMO Wire Anode

f) MMO Titanium Mesh Ribbon Anode

g) MMO Titanium Ribbon Anode

h)Titanium Conductor Bar

i) MMO or Platinized Probe Anode

2) Titanium Anode for Hydrometallurgy

3) Titanium Anode for Electrolysing Copper Foil

4) Titanium Anode for Electrolysing Aluminum Foil

5) Titanium Anode for Sodium Hypochlorite and Seawater Electrolysis

6) Titanium Anode for Electrolysing Organic Synthesis

7) Noble Metal Compounds

8. Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

1.A Kind of Brushing Device Used in Production of Titanium Ribbon and Titanium Mesh Ribbon

2.Dipping solution of the Coordination Compounds of Platinum and Prepare the Platinum Coating with it.

3.A Titanium Anode Device Used in a hydrometallurgical Electrodeposition of Metals

4.The Method of Removing Titanium Anode Coating

9. Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

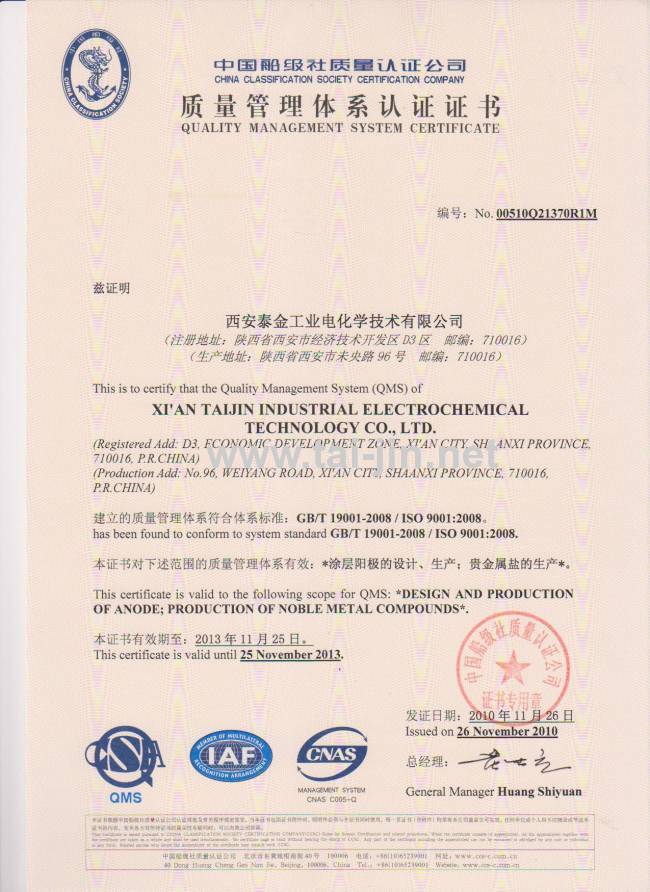

10. Quality Assurance

The Testing Procedures and Items

The Certificates of ISO9001

Quality Guarantee:

(1) Main quality indicators: titanium substrate, precious metal ratio, accelerated life, coating binding force to the titanium substrate/coating adhesion

(2) With advanced technology & equipment, abundant experiences and skilled workers,during the production of Titanium Anode, each process must be strictly supervised and tested, including the surface treatment of titanium material, coating quality, coating evenness, coating binding force to the titanium substrate and so on.

(3) We have own R&D, Production and Sales department, we always struggling to supply the product with the most excellent quality and the most favorable price and supply the most efficient service.

(4) Strict Pre-delivery inspection for each order, the original Mill Test Certificate available to attach to the delivery

(5) Warmly welcome you send inquiry to us.

Xi'an Taijin Industrial Electrochemical Technology Co., LTD. [China (Mainland)]

Business Type:Manufacturer

City: Xi'an

Province/State: Shaanxi

Country/Region: China (Mainland)