|

Xi'an Taijin Industrial Electrochemical Technology Co., LTD.

|

| Price: | 50.0~1000.0 USD |

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Ir-Ta coated titanium anode for Aluminium foil making

Specifications

1.Gr1 titanium substrate, precious metal Pt,Ru,Pb,Ta,Ir coating

2.As anode used for Aluminum Foil Forming

Titanium Anode for Aluminum Foil Forming | |

Material | Gr1 Titanium as substrate, mixed Iridium -Tantalum oxide as coating |

Technology | Sand blasting,Acid washing and Brush Coating |

Dimension & Shape | Different dimension and shape is available, or according to client's drawing |

Working Parameter | 1. Current density≤2000A/M2 2. PH 0.1~14 3. Max content of Fluoride ion is 200PPM |

Features | 1. High anti-corrosion property 2. Lasting working life 3. High current efficiency property 4. High catalytic property 5. Light weight 6. Keep the operating voltage stably 7. High purity of cathode material production 8. Saving electricity,etc. |

Remarks | 1. Titanium anode also called MMO anode,DSA & Insoluble anode 2. Cathode also be provide 3. Small sample order available |

Packing | Plastic or paper as inside, plywood case or carton as outside, or according to client's demand |

1. Primary Competitive Advantages:

Price

Guarantee/Warranty

Product Performance

Small Orders Accepted

Experienced Staff

Military Specifications

Prompt Delivery

2. Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

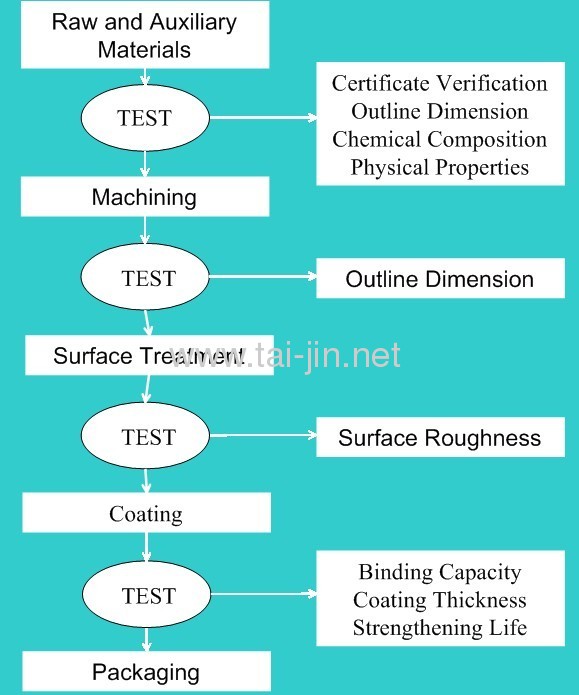

3. Producing Process

Raw material --- Shearing --- Punching Mesh ---Cutting--- Picking----Automatic coating ---Inspection---Package

4. Projects & Patents

a) Projects:

1.High Effective and Energy Saving Titanium Anode Used for Hydrometallurgy

2.The Development of Green and Novel Glass-to Metal Sealing Product

3.The Research and Production of High performance of Titanium Anode Composite Materials

4.The Research and Production of the Cathode Drum Used in Electrolyzing Copper Foil

b) Patents

5. Quality Assurance

Accelerated Life Test Coating Thickness Test