|

Xi'an Taijin Industrial Electrochemical Technology Co., LTD.

|

| Price: | 50.0~1000.0 USD |

| Place of Origin: | Shaanxi, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Iridum and Tantalum Oxide Coating Insouble Titanium Anode for Copper Foil

1. Substrate:

Pure titanium Gr1

1)Composition

C | max 0.08% |

N | max 0.03% |

H | max 0.015% |

Fe | max 0.20% |

O | max 0.18% |

Residual | max each 0.1% |

Residual | max total 0.4% |

Ti | balance |

2) Coating: Mixed Metal Oxide

2. Parameters

1) Coating Thickness: 12 microns

2) Current density≤12000A/M2

3) PH 0.1~14

4) Max content of Fluoride ion is 200PPM

3. Features

1) High electric catalytic property

2) High anti-corrosion property

3) High current efficiency property

4) Keep the operating voltage stably

5) Long lifetime

6) Different complex geometry design

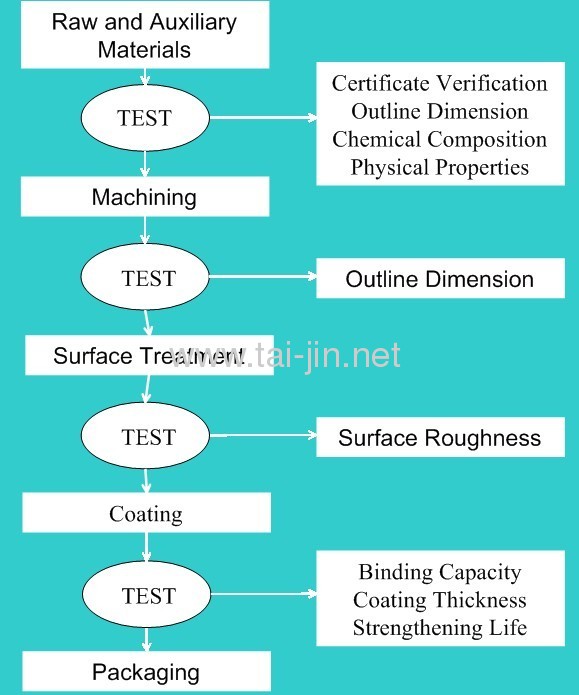

4. The flow of MMO Titanium Anode

Raw material --- Shearing ---Machining --- Blasting --- Picking ----Automatic coating---Inspection---Package

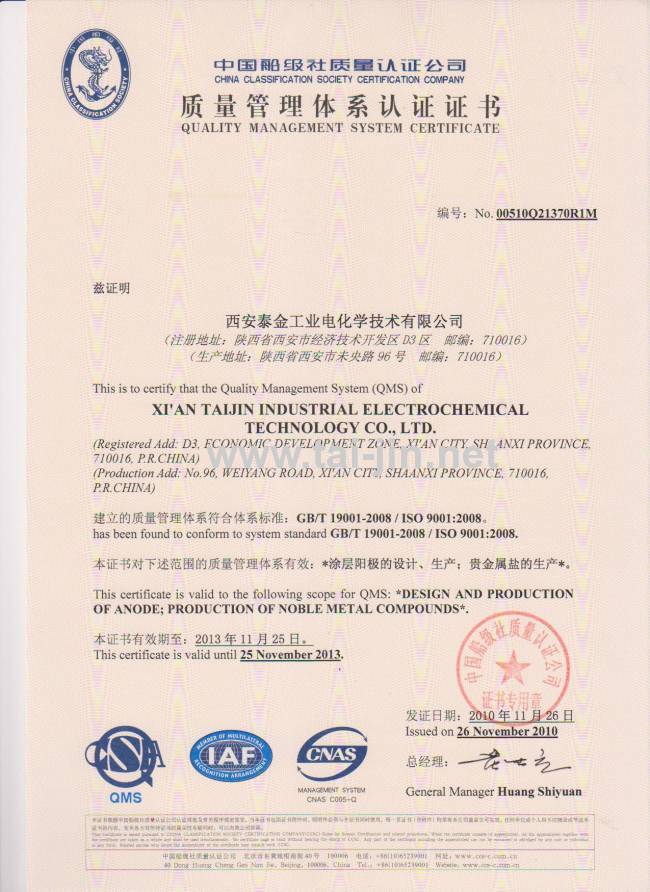

5. Quality Assurance

The Testing Procedures and Items

The Certificates of ISO9001

Quality Guarantee:

(1) Main quality indicators: titanium substrate, precious metal ratio, accelerated life, coating binding force to the titanium substrate/coating adhesion

(2) With advanced technology & equipment, abundant experiences and skilled workers,during the production of Titanium Anode, each process must be strictly supervised and tested, including the surface treatment of titanium material, coating quality, coating evenness, coating binding force to the titanium substrate and so on.

(3) We have own R&D, Production and Sales department, we always struggling to supply the product with the most excellent quality and the most favorable price and supply the most efficient service.

(4) Strict Pre-delivery inspection for each order, the original Mill Test Certificate available to attach to the delivery

(5) Warmly welcome you send inquiry to us.

6. Main Export Markets:

Asia

Australasia

Central/South America

Eastern Europe

Mid East/Africa

North America

Western Europe

7. Equipment

Machining Equipment

Precise Temperature Control Resistance Furnace

Accerlerate Life Test

Coating Thickness Test